Wholesalers have a major advantage over retailers because wholesalers know exactly what their customers want. Retailers can train their staff to ask, “Did you find everything you were looking for?” and hope that 1) shoppers are honest, and 2) there is actual follow-up from the staff to determine if the shoppers’ needs are fully met. There are tools that help retailers predict what shoppers want, but even these methods aren’t perfect.

Wholesalers, on the other hand, have access to order entry data, which is worth more than gold when properly used. The key to using order entry data for demand forecasting is you need to be able to filter the data appropriately during periods of out-of-stock, particularly in a ship-and-cancel environment. This is because when a certain SKU is out of stock, wholesale customers will place repeat orders until the item is back in stock. As a result, demand will be overstated in your forecasting and replenishment software.

HIMPACT overcomes this challenge by offering a tool called Service and Lost Sales Analysis (SALSA). For more information on SALSA, check out our other blog on how and why SALSA works.

Essentially, SALSA solves the issue of demand being overstated when using order entry data, which helps wholesalers know the true demand for all their SKUs. Yet, there is another challenge that needs to be overcome to use order entry data to its fullest potential: B2B Portals.

B2B Portals and Order Entry Systems

B2B portals offer many benefits. However, portals and systems that do not allow the capture of orders for items that are out of stock are unintentionally hurting your sales. Imagine if your sales team can only sell items you have on hand. The advantage to the sales team is time savings, certainly, but if there is no real substitute for missing items, you will lose sales. Further, even when there is an acceptable substitute, it isn’t what the customer really wanted. They will take note of this and may eventually start shopping elsewhere. Even if they don’t go to a competitor, this practice can negatively impact your reputation as a supplier.

There is value in being transparent about what is in stock so that you do not frustrate your customers. Are you aware of what you are giving up by avoiding full inventory transparency? If your portal only displays the items on hand each day, customers cannot convey what they really want. Worse, you have no way to measure actual lost sales.

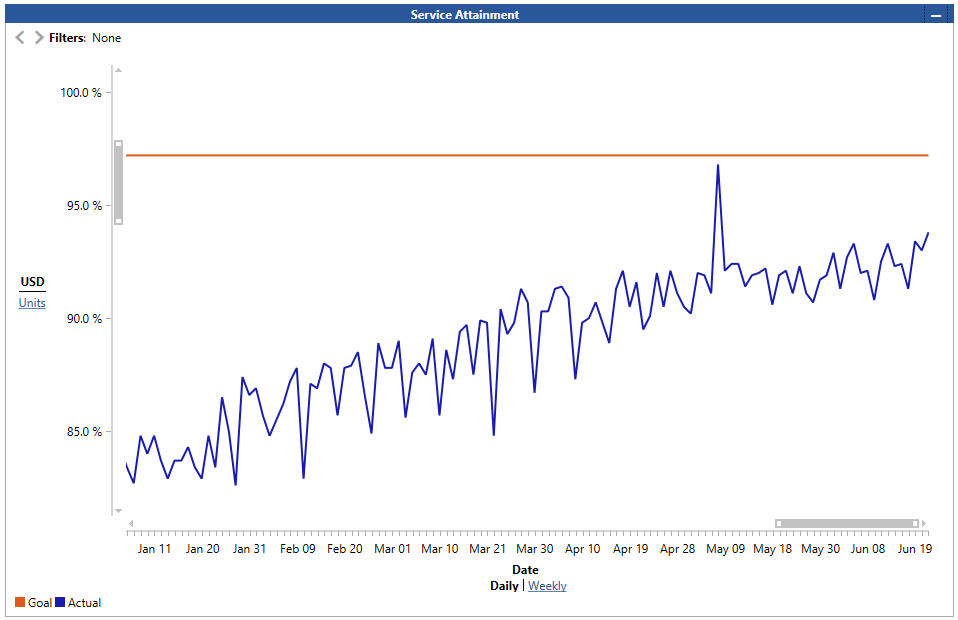

One of our clients thought they were servicing their customer base at 96-97% until they started using HIMPACT. When the system started using their order entry data as opposed to their invoice data, they realized that they were undeserving their customer base by over 10%. Using HIMPACT, they improved their fill rate from 87% to 97% in a matter of months and they reduced their inventory by 5%. How much would a top-line growth of 10% mean to you?

Is there a way to have both? Can we make both our B2B portals and order entry software capture what customers really want and not frustrate them by letting them order items that will end up being cut or substituted without notice prior to the delivery? There is, and you may have experienced it already.

Have you ever shopped online and as you get to the checkout, there is a message like:

“Item ABC is currently backordered until some date. Would you like to place this order now and ship it to you after it arrives, or would you like to order from a list of similar items that others have purchased instead?”

Attitude and Discipline

The answer is simple: show your entire item list. Let customers order what they want and for any item(s) that you currently cannot ship, let them know and offer substitutions where available. The real discipline must be in the sales team.

It is defeating to enter multiple orders for items that you already know are out of stock. However, sales incentives work. Train and incentivize your sales teams to enter these orders. HIMPACT users have seen top-line sales increase significantly, and customer goodwill also improved.

Consider Software Setting Changes or Enhancements

A final limitation to note is that many wholesale order entry systems, particularly the mobile ones, don’t have support for ordering items that are out-of-stock, or for managing the recovery at the time the order is placed. Your current solution may already have these capabilities, but it’s possible your system is configured to prevent this. Now is a great time to reevaluate how your system is handling order entries for out-of-stock items.

A Final Message

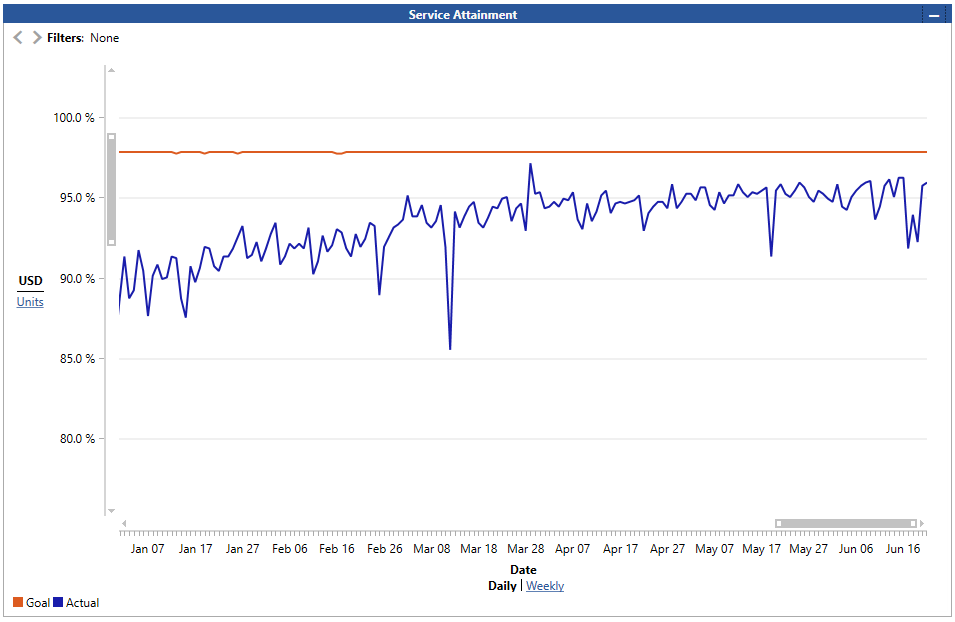

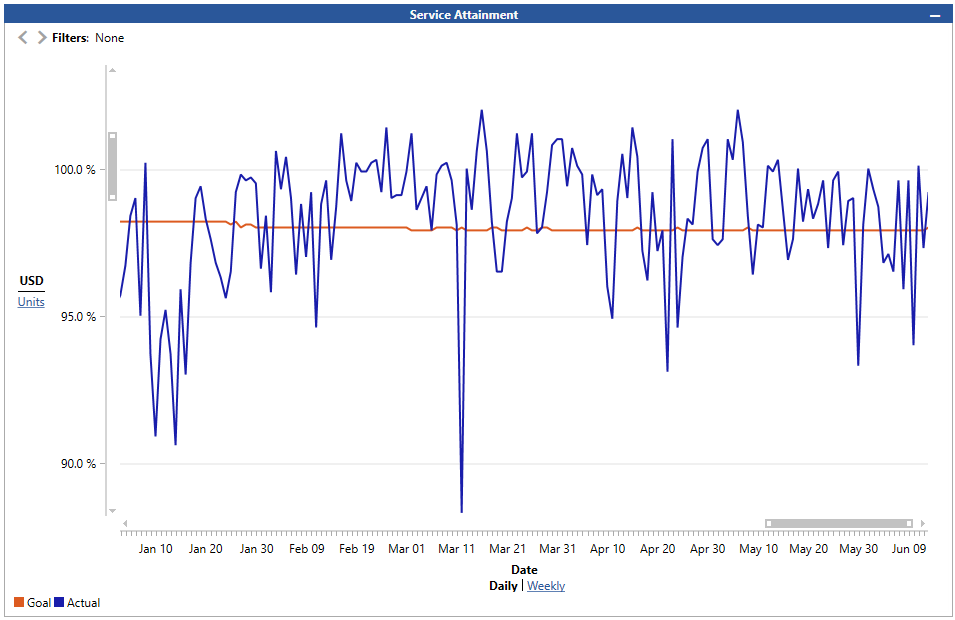

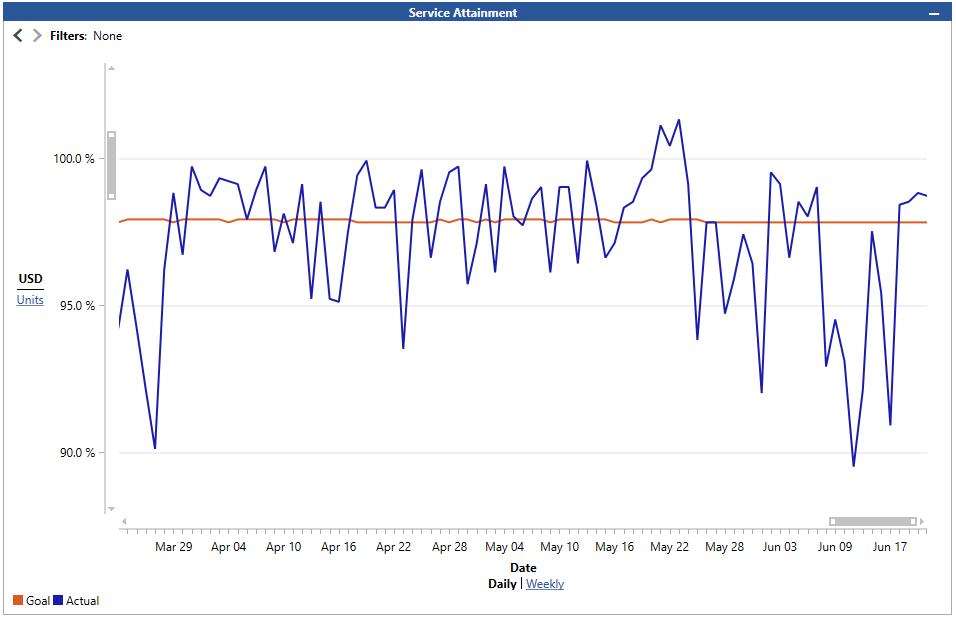

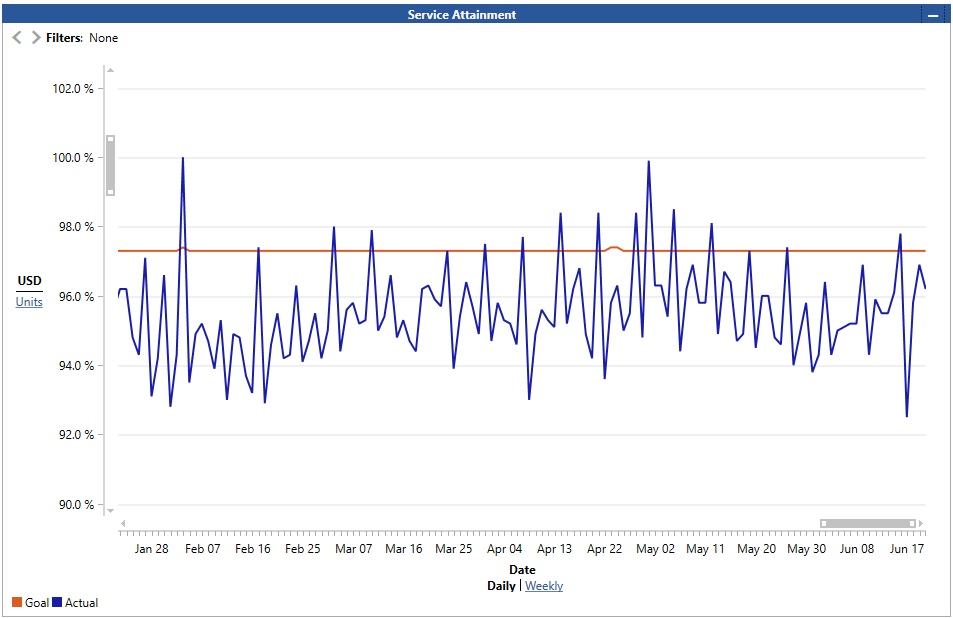

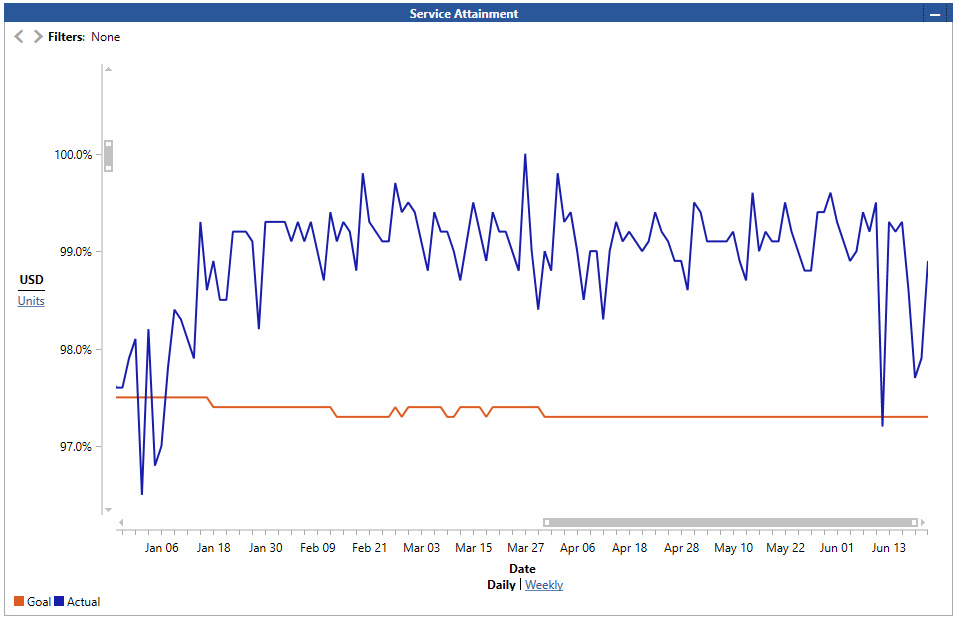

Without this data, how can you know if you have or have not recovered from the COVID-induced supply chain disruptions? Before the pandemic, all of the companies below were successfully meeting their service level goals. These companies are in three different industries with single or multiple warehouses. Thanks to HIMPACT, some are on the road to full recovery, while others have already made it back to pre-pandemic levels as you can see in the charts below.