Buyer’s Newsletter – Long Term Outs

Long Term Outs have now become the norm instead of the exception. Buyers are being increasingly forced to deal with them. Here we talk about best practices within HIMPACT to deal with these situations so buyers are able to handle long term outs and react as best they can.

How to Manage Long Term Outs in HIMPACT

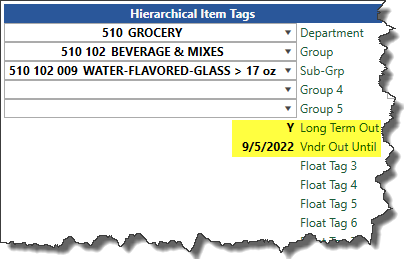

Step 1: Identify items using a Float Tag

The first step is to identify these items by using a Float Tag (Item or SKU), so it shows on the top of the Item Forecasting and Maintenance Tabs. These items can be sorted by using the view or the “sort” function within the items list. We also recommend utilizing Notes (Item or SKU) to identify them as well.

Step 2: Understand the Timeframe

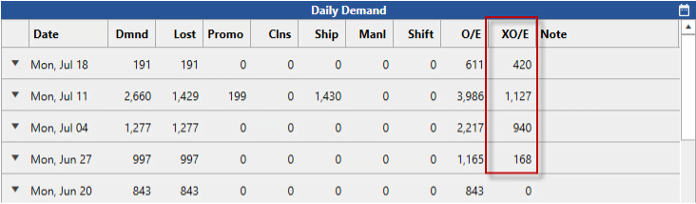

The second step would be to understand the length of the out-of-stock period, which can be complicated to find.

Remember, you can update these items using the standard interface, excel uploads, or directly in the UI. Once the items are appropriately tagged, you can use Mass Maintenance to remove or extend them.

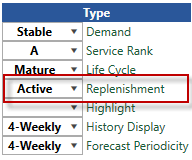

If you expect to be out of inventory for 1-6 weeks, then SALSA cleansing will help keep your forecast very close to reality. Your next move should be to Highlight the item, so it shows as Red on your Order tab. This will help you pay attention to the demand and forecast as you order.

If you know an item will be out for longer than 6 weeks, you have a few options to consider. For vendors that want you to discontinue ordering:

1.

Set the item to Replenishment Type “Manual” and then reactivate it via interface after the item becomes available

OR

2.

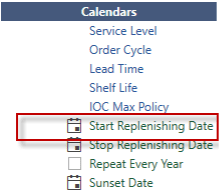

Use HIMPACT’s SKU level Start and Stop Dates. The advantage is that if the buyer has made the item discontinued, when the start date is reached, the item will not revert to Active.

AND

3.

Interface over the “not available until date” in an item float tag so users understand why the item is manual and for how long.

Many vendors are now providing a “not available until date” or a “recovery date.” The vendors convey this data because they do not want their wholesale customers clogging the system with orders for unavailable items, and it gives the wholesaler and manufacturer an opportunity to work together to plan out what will actually be needed for the inevitable Pipeline Refill Order.

For vendors that want you to keep ordering, we still recommend using both indicators, but also you should freeze the forecast. With the Long Term Out indicator set on the item or SKU, you can easily keep extending the Freeze Forecast Until Date on hundreds or thousands of SKUs in seconds as the weeks and months tick by using Mass Maintenance.

Another route for handling Long-Term Outs (LTO) is to use an Event Plan. The Event Plan tells HIMPACT that cap the existing forecast off at its specific level starting on one date and ending on a later date. By doing so, you can prevent the lost sales from inflating any demand above and beyond SALSA cleansing.

This practice is a little easier to manage because 1) it is at the source level, 2) the end date can be adjusted sooner or later and allows the user to select as many items on the source as necessary. You can also use this method to capture the LTO’s of a Source, which enables the user to look back and see what happened at the source and item levels.

As always if you have any questions concerning these steps or want some help walking through it, please reach out to your buyer support team at support@herlitzim.com